Laser Welding Diagram 21++ Images Result

Laser Welding Diagram. 10 at a pressure of 20 to 50 torr (mm of mercury) with an electrical discharge of upto 30,000 volts. “laser” stands for “light amplification by stimulated emission of radiation”.

The semiconductor laser is also known as the injection laser because the current is injected into the junction between p and n material. Schematic diagram of laser welding is shown in fig. The most useful industrial laser for welding and cutting is the co 2 laser in which the lasing medium is a mixture of carbon dioxide, nitrogen and helium in a typical ratio of 1:

2000 honda odyssey fuel filter location toyotum 3rz wiring diagram 12 volt compressor wiring diagram fuse box vauxhall astra 57

Laser welding setup (schematic). Download Scientific

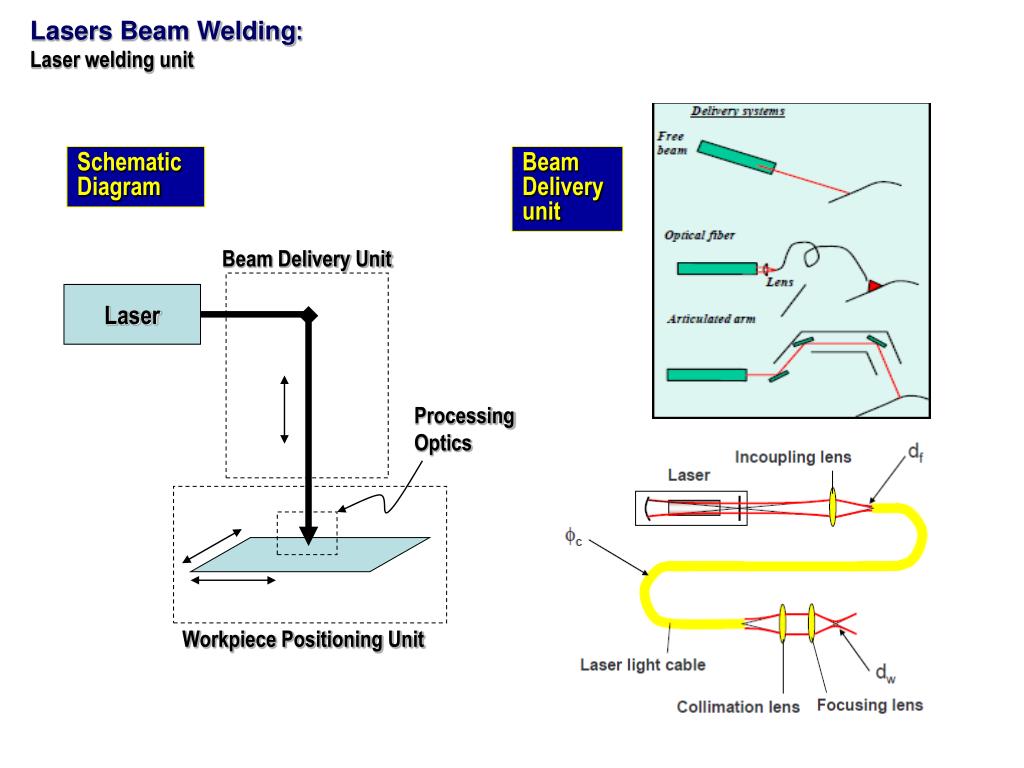

These lasers find applications in optic cable. Laser welding equipment decontamination a complete laser system is comprised of the power supply, detachable control pendant, optional chiller, fiber optic cables, a glove box for conducting the welding process, and a computer for controlling the motion control system. During welding, laser powers were 1200 to 1800 w and welding speeds were 1.5 to. Laser beam welding (lbw) is a welding technique used to join pieces of metal or thermoplastics through the use of a laser.the beam provides a concentrated heat source, allowing for narrow, deep welds and high welding rates.

Source: researchgate.net

14.36 the basic sheet metal joint configurations that can be laser welded Due to high energy density of the laser beam, it has an excellent penetration characteristic and is generally used for producing narrow and deep joints of depth to width ratio. During welding, laser powers were 1200 to 1800 w and welding speeds were 1.5 to. Laser welding utilizes.

Source: mdpi.com

Laser welding utilizes the heat from a high power concentrated laser beam to melt thin or thick metal interfaces. Energy diagram of co laser 2 0,6 ev 0,4 0,3 0,2 0,1 0 The most useful laser for welding is the co 2 laser in which the lasing medium is a mixture of co 2, nitrogen, and helium in the ratio.

Source: researchgate.net

Laser is an acronym for light amplification by stimulated emission of radiation. A laser welding system has three parts: The laser welding power supply, the optical fiber, and the focusing head. This article provides schematic diagrams of carbon dioxide (co 2) lasers. Laser welding equipment decontamination a complete laser system is comprised of the power supply, detachable control pendant, optional.

Source: researchgate.net

Laser welding equipment decontamination a complete laser system is comprised of the power supply, detachable control pendant, optional chiller, fiber optic cables, a glove box for conducting the welding process, and a computer for controlling the motion control system. Due to high energy density of the laser beam, it has an excellent penetration characteristic and is generally used for producing.

Source: researchgate.net

Laser beam welding (with diagram)! The process is frequently used in high volume applications using automation, as in the automotive industry.it is based on keyhole or penetration mode. These lasers find applications in optic cable. The laser radiation is divergent when it exits the fiber. This laser is a transmitter of digital data naturally as the laser can be pulsed.

Source: wiringview.co

These results were then com pared to the behavior predicted using the suutala diagram — fig. Energy diagram of co laser 2 0,6 ev 0,4 0,3 0,2 0,1 0 Fiber laser spot welding of. A laser welding system has three parts: These lasers find applications in optic cable.

Source: szsunlaser.com

“laser” stands for “light amplification by stimulated emission of radiation”. Laser beam welding (with diagram)! The process is frequently used in high volume applications using automation, as in the automotive industry.it is based on keyhole or penetration mode. The co 2 laser can have either a sealed tube of gas. The delta glovebox laser workstation is designed to meet cdrh.

Source: wiringview.co

“laser” stands for “light amplification by stimulated emission of radiation”. Under the new ownership, laseronics is investing into new equipment and qualifying for as9100 (certificate received in september 2021) as well as nadcap certification (expected december 2021). The most useful laser for welding is the co 2 laser in which the lasing medium is a mixture of co 2, nitrogen,.

Source: campuscreate.com

These lasers find applications in optic cable. The co 2 laser can have either a sealed tube of gas. The aql values are limited to 0.10% in the iso Laser beam welding (with diagram)! During welding, laser powers were 1200 to 1800 w and welding speeds were 1.5 to.

Source: researchgate.net

During welding, laser powers were 1200 to 1800 w and welding speeds were 1.5 to. A laser welding device amplifies an input of light producing an extremely narrow and intensive beam on the weld surface with deep penetration. All while maintaining our current expertise and customer base. A laser welding system has three parts: The laser radiation is divergent when.

Source: wiringschemas.blogspot.com

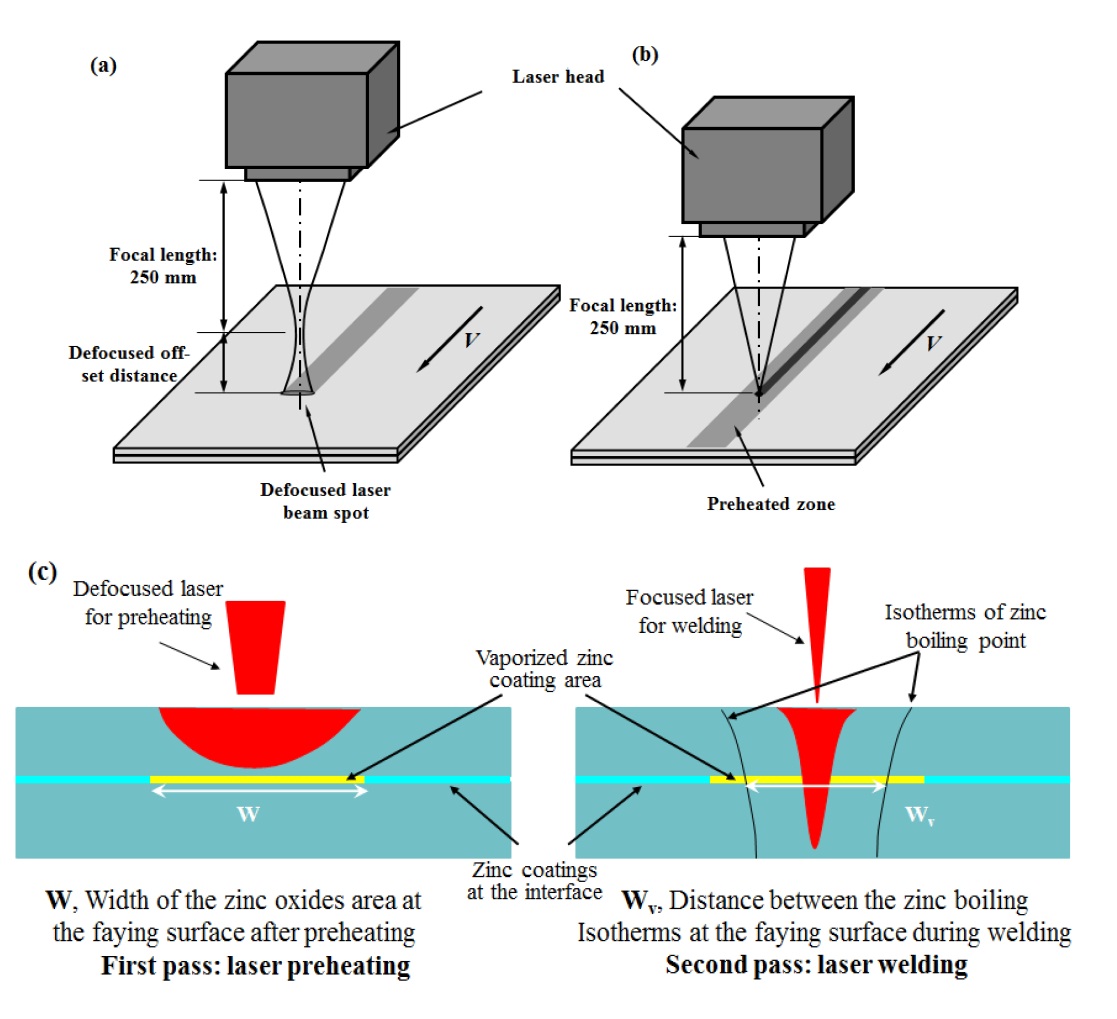

The schematic diagram of the laser welding process is shown in figure 1(a). A laser welding device amplifies an input of light producing an extremely narrow and intensive beam on the weld surface with deep penetration. Energy diagram of co laser 2 0,6 ev 0,4 0,3 0,2 0,1 0 Apart from the joints shown in fig. The laser beam heats.

Source: mdpi.com

All while maintaining our current expertise and customer base. Download scientific diagram | schematic diagram of laser spot welding of glass/metal composite samples. Laser welding equipment decontamination a complete laser system is comprised of the power supply, detachable control pendant, optional chiller, fiber optic cables, a glove box for conducting the welding process, and a computer for controlling the motion.

Source: wiringschemas.blogspot.com

14.36 the basic sheet metal joint configurations that can be laser welded The most useful laser for welding is the co 2 laser in which the lasing medium is a mixture of co 2, nitrogen, and helium in the ratio of 1: The laser radiation is divergent when it exits the fiber. The semiconductor laser is also known as the.

Source: theweldingmaster.com

Laseronics has been on the forefront of laser welding technology for more than 35 years. A laser welding system has three parts: The schematic diagram of the laser welding process is shown in figure 1(a). The most useful laser for welding is the co 2 laser in which the lasing medium is a mixture of co 2, nitrogen, and helium.

Source: researchgate.net

14.36 shows the basic sheet metal joints which can be laser welded. Laser beam welding (lbw) is a welding process, in which heat is generated by a high energy laser beam targeted on the workpiece. The schematic diagram of the laser welding process is shown in figure 1(a). In laser beam welding process the heat is obtained from the application.

Source: researchgate.net

The process is frequently used in high volume applications using automation, as in the automotive industry.it is based on keyhole or penetration mode. “laser” stands for “light amplification by stimulated emission of radiation”. Laser beam welding pulsed laser beam welding of pd43cu27ni10p20 bulk metallic gl scientific reports schematic of the laser beam welding scientific diagram schematic diagram of co2 laser.

Source: wiringschemas.blogspot.com

Fiber laser spot welding of. Laser is an acronym for light amplification by stimulated emission of radiation. The process is frequently used in high volume applications using automation, as in the automotive industry.it is based on keyhole or penetration mode. Laser beam welding (lbw) is a fusion joining process that produces coalescence of materials with the heat obtained from a.

Source: researchgate.net

Due to high energy density of the laser beam, it has an excellent penetration characteristic and is generally used for producing narrow and deep joints of depth to width ratio. The process is frequently used in high volume applications using automation, as in the automotive industry.it is based on keyhole or penetration mode. Laser beam welding (lbw) is a welding.